As industries push the limits of performance, one material is quietly enabling innovation across defense, aerospace, energy, and precision manufacturing: Samarium Cobalt (SmCo) Permanent Magnets.

Often overshadowed by their Neodymium counterparts, SmCo magnets are gaining prominence due to their exceptional thermal stability, resistance to demagnetization, and long-term durability in mission-critical environments.

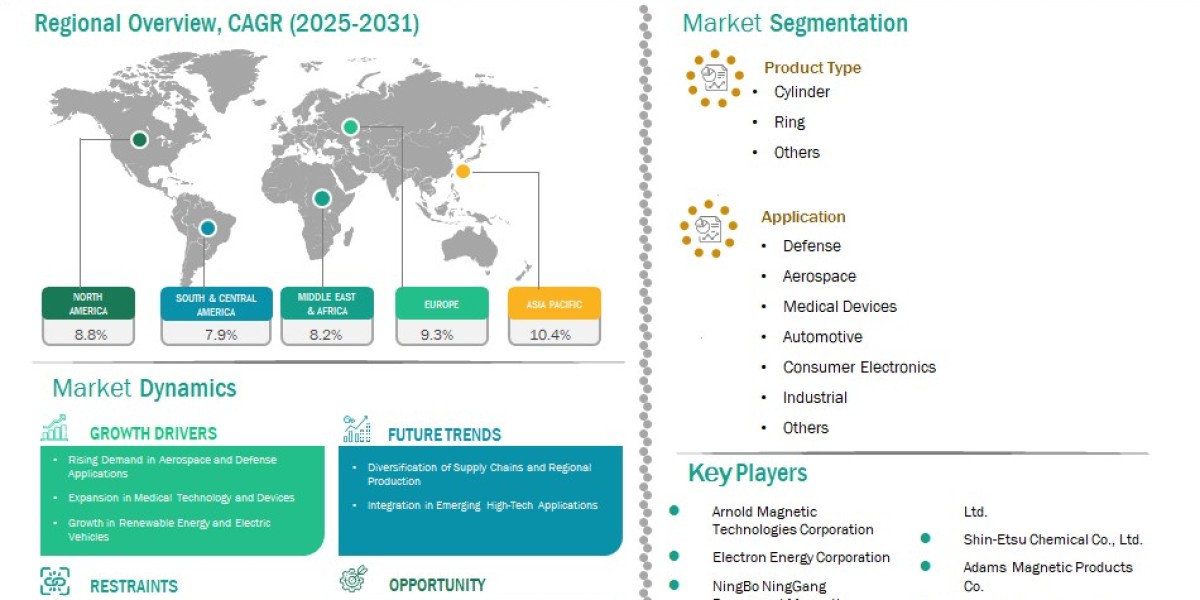

According to Business Market Insights, the Samarium Cobalt Permanent Magnet Market is set to grow steadily through 2030, driven by strategic applications in harsh, high-performance settings.

? The Science Behind SmCo Magnets

Samarium Cobalt magnets are a class of rare-earth magnets engineered from a blend of samarium (Sm) and cobalt (Co). Their properties include:

High magnetic strength, even at elevated temperatures

Thermal stability up to 350°C, far beyond Neodymium

Corrosion resistance without external coatings

Excellent demagnetization resistance

These traits make SmCo magnets ideal for:

Aerospace control systems

Electric motor assemblies operating in extreme heat

Nuclear, oil & gas, and marine environments

High-reliability medical and military devices

⚙️ Industrial Use Cases

? Aerospace & Defense

SmCo magnets are preferred in:

Missile guidance and navigation systems

Actuator control in aircraft

Military-grade radar and secure comms

Spacecraft propulsion systems

Their high reliability in vacuum, radiation, and fluctuating temperatures makes them irreplaceable for satellite and orbital technologies.

⚡ Energy & Utilities

SmCo magnets are used in:

Offshore wind turbines

Gas turbines

High-speed alternators and generators

Smart grid sensors in high-load zones

Their performance longevity contributes to lower maintenance and enhanced operational safety in high-value equipment.

? Electric Vehicles

While Neodymium dominates consumer EVs, SmCo is gaining favor for:

High-efficiency traction motors in military, industrial, or heavy-duty EVs

Applications requiring thermal resilience and extended operating life under load stress

? Medical & Micro-Mechanical Systems

Used in:

Robotic surgical instruments

Miniature medical pumps

MRI-compatible actuators

High-resolution imaging drives

? Regional Outlook

North America – Strong demand from defense and aerospace contractors

Europe – Growth in green mobility and energy technologies

Asia-Pacific – Significant R&D and electronics manufacturing in China, Japan, South Korea

Middle East & Africa – Focused growth in industrial mining and energy infrastructure

? Key Manufacturers & Innovators

Leading companies in the SmCo market include:

Arnold Magnetic Technologies

Eclipse Magnetics

MS-Schramberg GmbH

Thomas & Skinner Inc.

Goudsmit Magnetics

These firms are investing in custom alloy compositions, smaller form factor magnets, and AI-driven material optimization.

? Market Growth Drivers

Global defense modernization and arms tech demand

Thermal-resilient electric motor production

Expansion of satellite and low-Earth-orbit (LEO) systems

New medical robotic devices with high-torque microdrives

Focus on lifecycle performance over cost in industrial design

? Future Outlook Through 2030

SmCo recycling systems will emerge to stabilize rare-earth material sourcing

Enhanced design simulation tools (digital twins) will tailor SmCo integration in early design phases

Growth in AI-augmented robotics and autonomous systems will drive miniaturized magnet development

Governments may invest in SmCo stockpiling for strategic technology independence

? Access the Full Market Report Here

? https://www.businessmarketinsights.com/reports/samarium-cobalt-permanent-magnet-market