As the vape industry continues to grow rapidly, selecting the right equipment is essential to produce high quality cartridges efficiently. Desktop vape cartridge filling machines offer a compact and affordable solution for startups and small to medium businesses looking to automate part of their production process. But with many models available on the market, it can be challenging to determine which features are most important. Choosing the right desktop filling machine means balancing precision, speed, ease of use, and durability. In this article, we will explore the key features to consider to ensure you invest in a machine that meets your business’s production goals and quality standards.

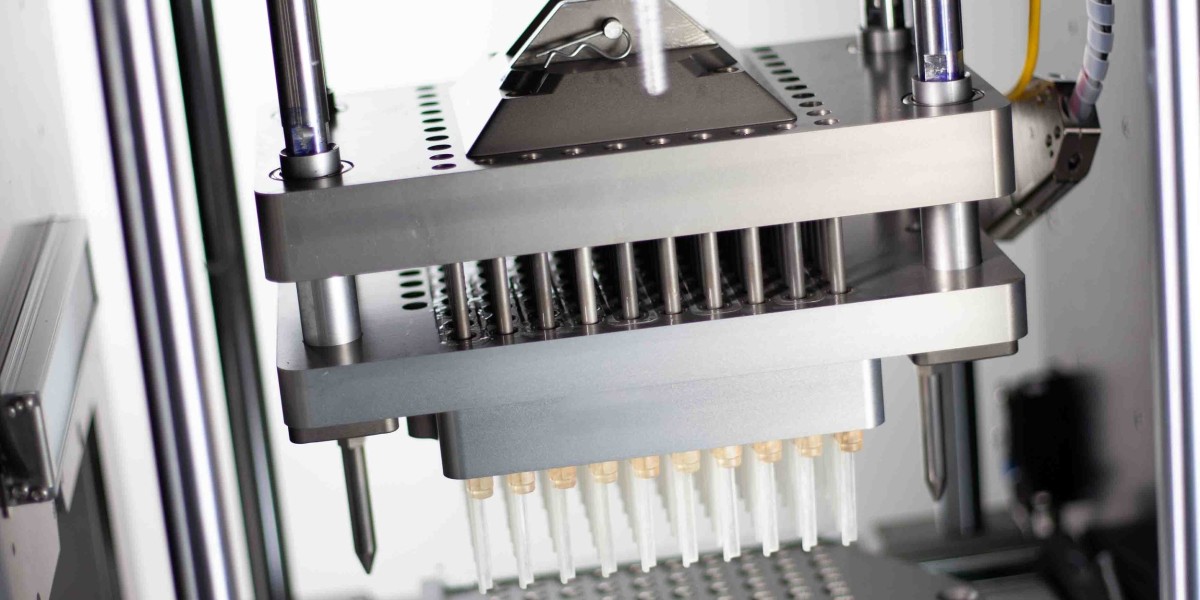

Accurate and Consistent Filling Mechanism

The most critical feature of any vape cartridge filling machine is its ability to deliver precise and consistent fill volumes. Accuracy ensures that each cartridge contains the exact amount of vape liquid specified, which is essential for regulatory compliance and customer satisfaction. Machines equipped with high-quality pumps, such as peristaltic or syringe pumps, provide reliable dosing control. Additionally, look for models that offer adjustable fill volumes, allowing you to tailor the machine to different cartridge sizes and product viscosities. Consistent filling reduces waste and overfilling, helping you maximize your raw material use and improve profitability.

User Friendly Interface and Controls

Ease of operation is key, especially if your production team includes staff with varying levels of technical experience. Desktop vape cartridge filling machines with intuitive touchscreen interfaces and straightforward controls simplify programming and adjustments. Clear displays showing fill volume, speed, and operational status help operators monitor the process effectively. Some machines also provide pre-programmed settings for common cartridge sizes, reducing setup time. A user-friendly interface minimizes training requirements and helps maintain consistent operation even with staff turnover, ensuring smooth production runs.

Compact and Space Saving Design

Desktop machines are valued for their small footprint, which makes them ideal for manufacturers working in limited spaces or those who want to avoid large capital expenditures. When selecting a filling machine, consider how much bench or floor space it occupies and whether it fits comfortably within your production area. Compact design should not compromise functionality; the machine should still accommodate various cartridge sizes and viscosities efficiently. Space saving equipment also allows you to expand production lines or add other equipment as your business grows, supporting scalability.

Adjustable Filling Speed and Throughput

Production speed is an important factor in meeting customer demand and optimizing workflow. Desktop vape cartridge filling machines vary in how fast they can operate, so consider the machine’s filling speed and overall throughput capacity. Adjustable speed controls allow you to optimize production based on your current volume needs without sacrificing accuracy. Machines that can handle moderate to high throughput while maintaining consistent filling quality provide the best balance for growing businesses.

Easy Cleaning and Maintenance

Maintaining hygiene and preventing cross contamination are crucial in vape manufacturing. The filling machine should have parts that are easy to disassemble and clean regularly. Look for models with stainless steel components or food grade materials that resist corrosion and buildup. Quick release fittings and modular designs simplify maintenance, reducing downtime and keeping production running smoothly. Regular cleaning also helps ensure consistent product quality and complies with industry standards.

Compatibility with Different Cartridge Types and Viscosities

The vape market includes a wide variety of cartridge designs and liquid formulations, ranging from thin distillates to thicker oils. Your filling machine should be versatile enough to handle different cartridge sizes and liquid viscosities without frequent adjustments or equipment changes. Features such as adjustable nozzles, variable pressure pumps, and flexible filling protocols allow manufacturers to switch between product lines efficiently. This adaptability supports product diversification and innovation, enabling businesses to meet evolving consumer demands.

Reliable Build Quality and Supplier Support

Investing in quality equipment reduces the risk of frequent breakdowns and costly repairs. Choose machines built with durable materials and components from reputable manufacturers. Additionally, strong after sales support from suppliers, including technical assistance, parts availability, and warranty services, is invaluable. Reliable service ensures that any issues are addressed promptly, minimizing production disruptions and maintaining operational continuity.

Automation and Integration Capabilities

While desktop filling machines are generally standalone devices, some models offer automation features such as conveyor integration, automated cartridge feeding, and programmable filling cycles. These features can enhance efficiency and reduce manual labor further. If you plan to expand your production or integrate the filling machine into a larger automated line, consider machines that support such connectivity or modular upgrades.

Conclusion

Selecting the right desktop vape cartridge filling machine requires careful consideration of several key features. Precision in filling, user friendly controls, compact design, and compatibility with various cartridges and viscosities are essential factors for success. Additional benefits such as adjustable speed, easy maintenance, durable construction, and supplier support ensure your investment delivers long term value. By choosing a machine with these features, vape manufacturers can improve production efficiency, maintain consistent product quality, and scale their operations effectively in a competitive market.

FAQs

What is a desktop vape cartridge filling machine?

It’s a compact machine designed to automate the filling of vape cartridges with precise amounts of liquid for small to medium production runs.

Why is fill accuracy important in vape cartridge machines?

Accurate filling ensures consistent product potency, meets regulatory standards, and reduces waste from overfilling.

Can desktop machines handle different cartridge sizes?

Yes, many desktop models offer adjustable settings to accommodate various cartridge types and liquid viscosities.

How important is ease of cleaning and maintenance?

Very important. Easy cleaning prevents contamination, maintains product quality, and reduces downtime.

Do desktop filling machines support automation?

Some models include automation features and can integrate with other equipment for improved efficiency.